The Uttarakhand tunnel collapse on November 12, 2023, involved a section of the Silkyara Bend – Barkot tunnel, part of the Char-Dham all-weather road project. Situated on the Yamunotri National Highway in Uttarkashi, the under-construction tunnel, also known as Silkyara Tunnel, trapped 41 workers. The National Disaster Response Force (NDRF), State Disaster Response Force (SDRF), and police launched immediate rescue operations. The incident, reminiscent of past occurrences, highlights the risks of infrastructure development in hilly terrains. The tunnel, under the central government’s Char Dham project, aims to connect Gangotri and Yamunotriaxis, enhancing accessibility in challenging terrains and promoting national security.

What does the Char-Dham project, highlighted by the recent Uttarakhand Tunnel Collapse, entail?

Char-Dham Project- It is a highway expansion project to widen 889 km of hill roads to provide all-weather connectivity in the Char Dham circuit. The project, envisaged in 2016, covers Uttarakhand’s four major shrines- Badrinath, Kedarnath, Gangotri and Yamunotri- in the upper Himalayas.

About the Silkyara Tunnel (Uttarakhand’s Tunnel which collapsed)-

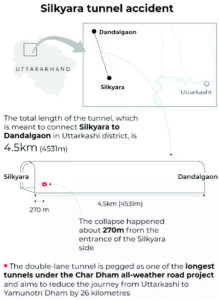

1. The total length of the tunnel of the tunnel is 4.5 Km. It is meant to connect Silkyara to Dandal-gaon in Uttarkashi district.

2. The double-lane tunnel is one of the longest tunnels under the Char Dham all-weather road project and aims to reduce the journey from Uttarkashi to Yamunotri Dham by 26 kilometres.

Collapse Site- The collapse happened about 270m from the entrance of the Silkyara side.

Previous Incidents of Collapse in Himalayas

1. The Subansiri Lower Hydroelectric Power Project faced a major setback when a landslide disrupted construction and blocked the project’s diversion tunnels.

2.Flash floods along the Teesta River inflicted damage on the Chungthang Dam and Teesta hydropower stations, resulting in substantial financial losses.

3.In 2015, the Kiratpur-Nerchowk Tunnel in Himachal Pradesh experienced a collapse, although specific details about the incident are not provided.

4.The Tehri Hydropower Project encountered a tunnel collapse in 2004, contributing to the challenges faced by Himalayan tunnel constructions.

5.Tragically, in February 2021, the Tapovan-Vishnugad Hydel Project witnessed one of the deadliest incidents in Uttarakhand’s history. Over 100 workers lost their lives after being trapped in a tunnel following a flash flood. The rescue operation extended for months, recovering bodies from the Head Race Tunnel.

6. Llast month, nearly 40 workers narrowly escaped a potentially disastrous situation when a fire broke out inside the under-construction tunnel of the Rishikesh-Karnprayag Railway Project in Rudraprayag district. The incident was attributed to a chemical catching fire within the tunnel.

Possible causes of Uttarakhand Tunnel Collapse

Uttarakhand Govt. forms committee to investigate Tunnel Collapse. Experts suggest potential causes:

1-Fractured rock weakness due to numerous joints.

2-Water seepage eroding rock, creating voids.

3-Young Himalayan rock system prone to landslides.

4-Doubts about conducting geological studies before tunnel excavation.

5-Lack of protection measures in the shear zone.

6-Failure to design an escape tunnel for emergencies.

Besides these reasons given by experts, questions have been raised on the fragility of the Himalayas in sustaining massive infrastructure projects like the Char-Dham project, massive hydroelectric power projects.

Steps to ensure safe tunnel construction

1-Enhance geotechnical studies for concurrent tunnel design and construction, incorporating detailed analyses like petrographic analysis for a more comprehensive approach.

2-Ensure regular monitoring by independent specialist geologists during site visits to detect potential failures and determine the rock’s stand-up time, essential for stability.

3-Rigorously test the adequacy of tunnel supports, including shotcrete, rock bolts, steel ribs, and tunnel pipe umbrellas, to prevent collapse.

4-Establish robust evacuation arrangements in case of a collapse, involving NDRF personnel, safety equipment, and mandatory safety plans from construction companies bidding on projects.

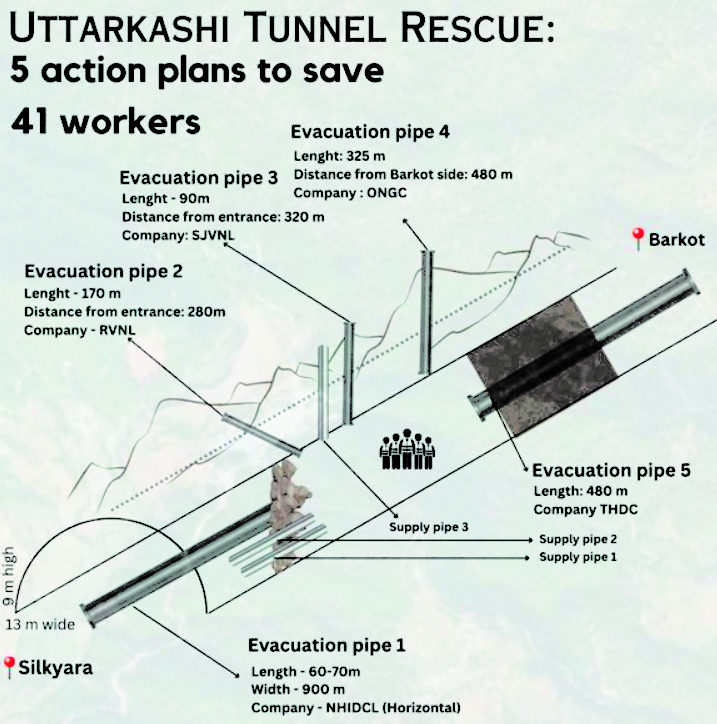

PLANS TO EVACUATE THEM

Authorities plan to evacuate trapped workers in five ways, utilizing various agencies: ONGC, SJVNL, RVNL, NHIDCL, and THDCL. The 8.5-meter-high, 2 km-long tunnel collapse requires a coordinated effort, with specific tasks assigned to each agency, as reported by the Ministry of Road Transport and Highways.

1. 1.2 metre-wide hole after vertical drilling

Rescuers plan a 1.2m-wide vertical hole, extending 90m to reach trapped workers in the Silkyara tunnel. Vertical drilling, crucial for accuracy, begins once the site is prepared. The first machine is on-site, and two more from Gujarat and Odisha are expected in two-three days, as per the newspaper report. SJVNL deploys a heavy drilling machine for the operation. Arnold Dix, overseeing the rescue as the ITA president, highlights multiple approaches to the Uttarkashi tunnel collapse rescue.

2. Horizontal boring by NHIDCL

Engineers faced challenges horizontally driving a steel pipe through 57 meters of earth and rock to reach trapped workers. The earth-boring machine encountered unyielding boulders, prompting a pause due to safety concerns after a cracking sound. The NHIDCL team plans to resume drilling from the Silkyara side using an Augur boring machine for the horizontal boring operation.

3. Another vertical tunnel from the top

The Oil and Natural Gas Corporation (ONGC), having expertise in deep drilling, has been tasked to create another verticle tunnel at the 2.3-km mark. This tunnel will be nearly 325 metre deep and the machines for this operation was brought from the US, Mumbai and Ghaziabad.

4. Rescue from Barkot end

A 483-metre-long yet narrower tunnel will be made through the Barkot end of the tunnel by the Tehri Hydro Development Corporation using the conventional drill and blast method.

5. Another horizontal drilling by RVNL

Rail Vikas Nigam Limited (RVNL) is constructing a 900mm-wide vertical pipeline for essential supply, utilizing micro-drilling from the left of the tunnel. The 1.2m-wide, 168m-long horizontal tunnel aims to connect with the existing tunnel around the 300-meter mark from the Silkyara side, providing a swift solution as per expert advice.